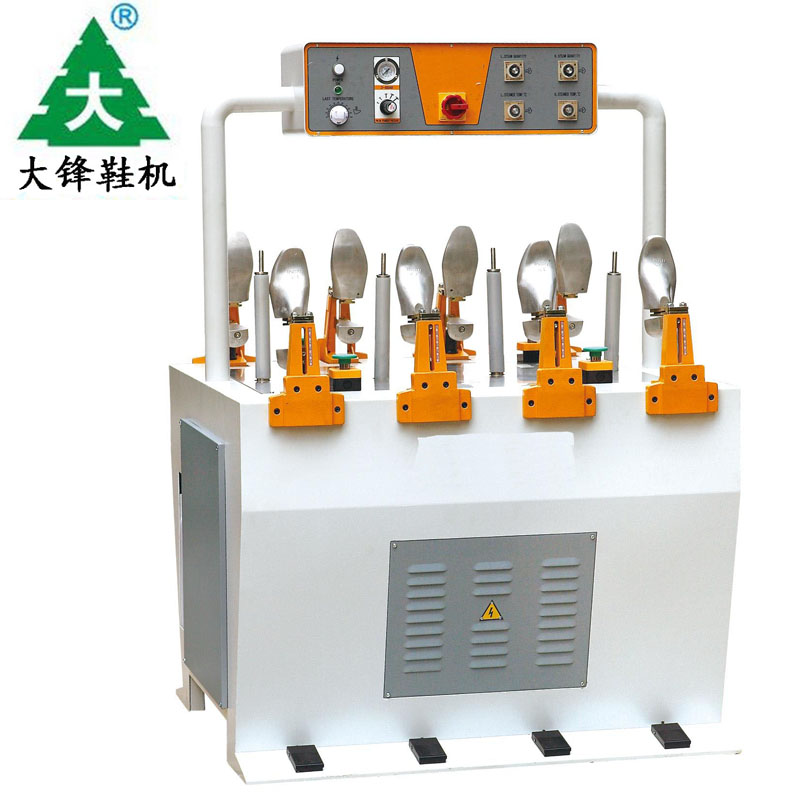

one cold and one hot backpart moulding machine for stitch-down shoes picture

one cold and one hot backpart moulding machine for stitch-down shoes feature

Professional to do the snow

boots manufacturers tailored, with the shape of good effect, stable quality,

economic and durable and so on

The internal

and external mold temperature can be adjusted individually, which can be applied

to the hot demand of the upper and the inner of various materials.

After a predetermined type heel sleeve

complete with uppers and lining adhesive, not out of the and it completely

leveled, improve the quality of the upper, reduce non-performing rate

The design and operation of the

inclined plane is simple and convenient.

Fixture can be used to adjust the itinerary or

choose not to apply a variety of different types of shoes

Mold according to customer shoe type custom, can

obtain the most accurate shape effect

special negative mold can be defective and integer, eliminate wrinkles and

increase the welt appearance

Environment protection of the unique

design of the refrigeration system, high efficiency, the fastest speed, up to -2

0

one cold and one hot backpart moulding machine for stitch-down shoes specifications

model | size | production | N.W | voltage | power |

DF-967 | 750×680×1600 | 600 | 200kg | 220V | 0.8KW |

one cold and one hot backpart moulding machine for stitch-down shoes picture

one cold and one hot backpart moulding machine for stitch-down shoes feature

Professional to do the snow

boots manufacturers tailored, with the shape of good effect, stable quality,

economic and durable and so on

The internal

and external mold temperature can be adjusted individually, which can be applied

to the hot demand of the upper and the inner of various materials.

After a predetermined type heel sleeve

complete with uppers and lining adhesive, not out of the and it completely

leveled, improve the quality of the upper, reduce non-performing rate

The design and operation of the

inclined plane is simple and convenient.

Fixture can be used to adjust the itinerary or

choose not to apply a variety of different types of shoes

Mold according to customer shoe type custom, can

obtain the most accurate shape effect

special negative mold can be defective and integer, eliminate wrinkles and

increase the welt appearance

Environment protection of the unique

design of the refrigeration system, high efficiency, the fastest speed, up to -2

0

one cold and one hot backpart moulding machine for stitch-down shoes specifications

model | size | production | N.W | voltage | power |

DF-967 | 750×680×1600 | 600 | 200kg | 220V | 0.8KW |