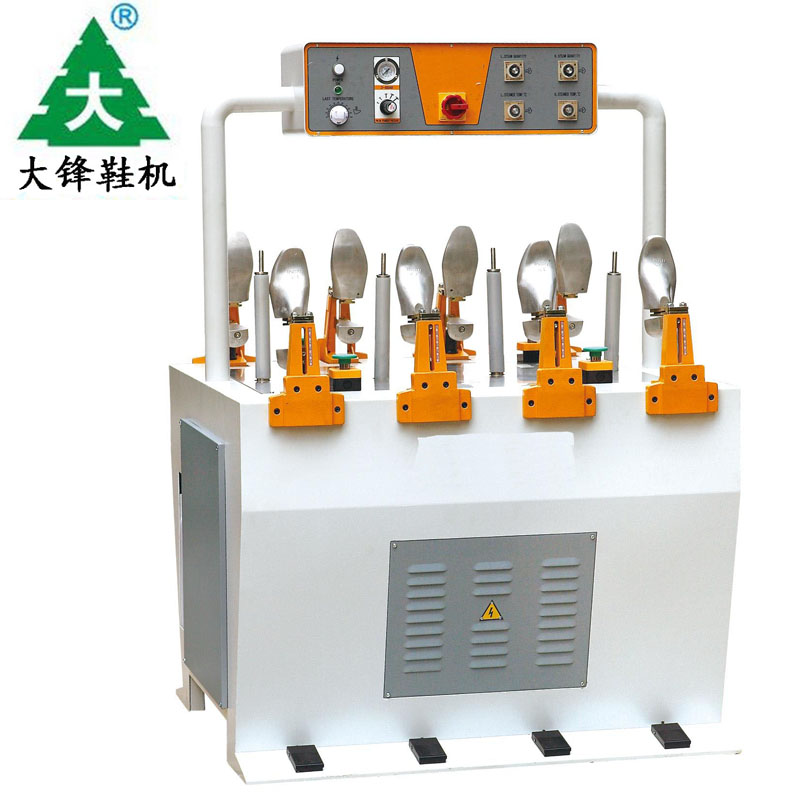

Backpart Moulding Machine

1. The temperature of inner and outer moulds can be regulated automatically according to different materials.

2. After moulding, the liner, rubber sheet and vamp are closely jointed without crinkling, deformation and bubbling.

3. The tilt manage plate to easy working.

4. The adjustable clamp will achieve 100% jointing of vamp with last.

5. The inner and outer moulds are made based on the last of customers, which will head to a perfect appearance.

6. The special mold can wrok in defective backpart.

7. The adoption of environment-friendly freezing system features high speed and good result with freezing temperature up to -20℃.

MODEL | Dimensions(L*W*H) | PRODUCTION | N.W | VOLTAGE | POWER |

DF-966 | 800*510*1590mm | 1200pairs/8jrs | 280kg | 380V/50Hz | 1.5KW |

Backpart Moulding Machine

1. The temperature of inner and outer moulds can be regulated automatically according to different materials.

2. After moulding, the liner, rubber sheet and vamp are closely jointed without crinkling, deformation and bubbling.

3. The tilt manage plate to easy working.

4. The adjustable clamp will achieve 100% jointing of vamp with last.

5. The inner and outer moulds are made based on the last of customers, which will head to a perfect appearance.

6. The special mold can wrok in defective backpart.

7. The adoption of environment-friendly freezing system features high speed and good result with freezing temperature up to -20℃.

MODEL | Dimensions(L*W*H) | PRODUCTION | N.W | VOLTAGE | POWER |

DF-966 | 800*510*1590mm | 1200pairs/8jrs | 280kg | 380V/50Hz | 1.5KW |