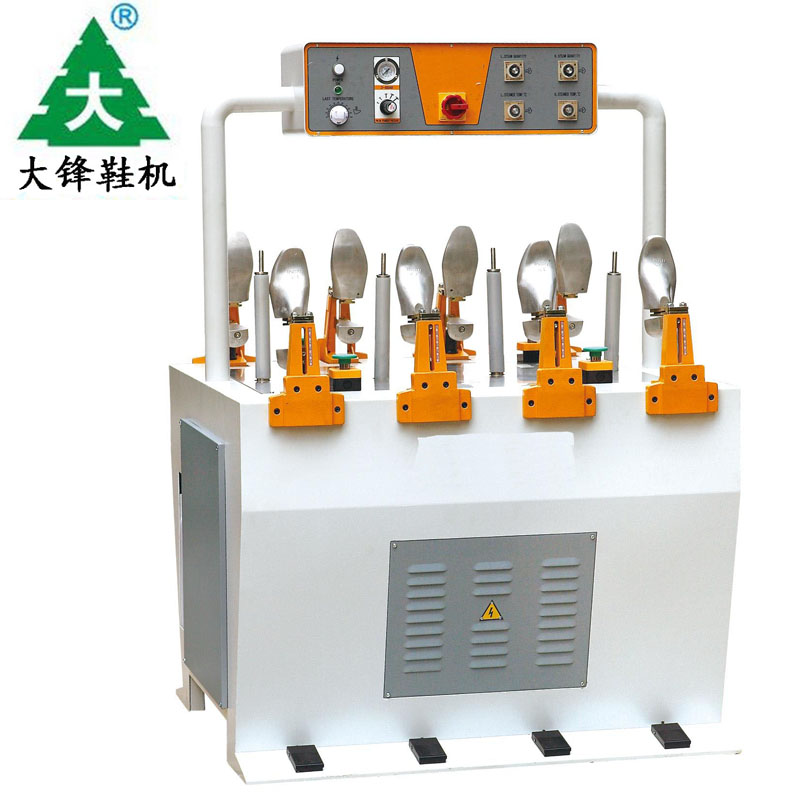

toe puff coupling machine,toe puff applying machine (2 stations)

1, The machine is mainly used for vamp leather and sheeting tip binding.

2, the material of sheeting tip can be pasted with vamp by pre-spraying

thermoplastic glue or pre-spraying glue over ordinary material and

coating with glue inside, then binding with vamp.

3, This machine adopts pneumatic driving and use upper and lower are

moulds to bind the vamp leather with sheeting tip. The binding shall

be done after the inside is coated with glue so that the vamp leather

and sheeting tip can be bound together as and integral part.

4, The design of are shape upper and lower moulds will facilitate the

processing later. The are upper mould is provided with heating device

to melt the pre-coated glue and will make the vamp firmer after pressing.

5, The time and temperature of pressing can be adjusted upon the

requirement of processed materials.

6, Under the lower mould, there is a small pole, which can conduct pressing

by upper mould after the sheeting tip is pressed in alignment, This design

can ensure accurate location of sheeting tip on vamp.

Technical Specifications:

number DF-870

Machine Size: 660*510*1630mm

N.W.: 100kgs

Air Pressure: 0.6Mpa

Power: 0.8Kw

Voltage: 220V/50Hz

toe puff coupling machine,toe puff applying machine (2 stations)

1, The machine is mainly used for vamp leather and sheeting tip binding.

2, the material of sheeting tip can be pasted with vamp by pre-spraying

thermoplastic glue or pre-spraying glue over ordinary material and

coating with glue inside, then binding with vamp.

3, This machine adopts pneumatic driving and use upper and lower are

moulds to bind the vamp leather with sheeting tip. The binding shall

be done after the inside is coated with glue so that the vamp leather

and sheeting tip can be bound together as and integral part.

4, The design of are shape upper and lower moulds will facilitate the

processing later. The are upper mould is provided with heating device

to melt the pre-coated glue and will make the vamp firmer after pressing.

5, The time and temperature of pressing can be adjusted upon the

requirement of processed materials.

6, Under the lower mould, there is a small pole, which can conduct pressing

by upper mould after the sheeting tip is pressed in alignment, This design

can ensure accurate location of sheeting tip on vamp.

Technical Specifications:

number DF-870

Machine Size: 660*510*1630mm

N.W.: 100kgs

Air Pressure: 0.6Mpa

Power: 0.8Kw

Voltage: 220V/50Hz